NISAKU Japanese Gardening Tools

70 Years of Excellence

The Nisaku Factory

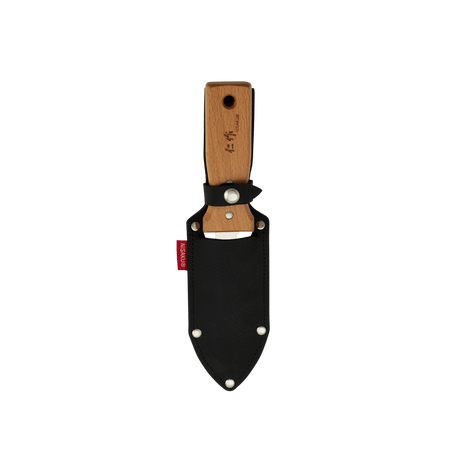

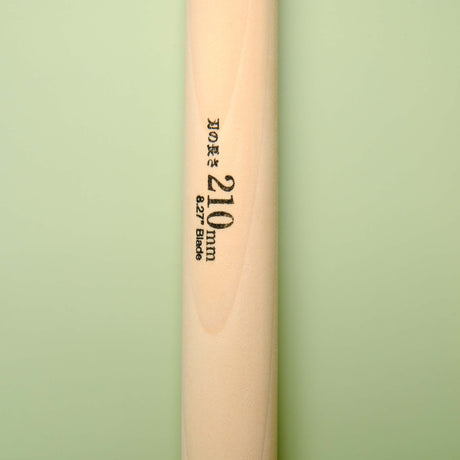

We are fortunate to work with some of the world's best manufacturers, and Nisaku's tools have long stood out from a very strong field.

Earlier this year Christian had the opportunity to tour the Nisaku facility, and he got a first hand glimpse of some production processes that set Nisaku's knives apart.

Of course, the hand-sharpening of the final edge is always impressive. Nisaku's smiths have ground more knives than they've had hot dinners, so it should be no surprise that our Horis come as beautifully sharp as they do. Watching a skilled craftsman at work is always a pleasure though.

Widely underappreciated, we think, is the time and machining that it takes to impart Nisaku's mirror finish on their tools. As well as being beautiful to behold (and difficult to photograph for our website), this finish also allows the tool to shed dirt and grime easily, making it easier to clean and even harder to corrode.

Christian got to witness Nisaku's surface finishing process up close and personal, and their abrasive-covered drums certainly aren't mucking around.

A final thing that impressed Christian greatly was the amount of custom forming that Nisaku does on water- and grinding-stones.

The process of manufacturing forms, which are then used to create custom grinding profiles, which are then used to grind specific edges (such as the Hori's serrations) is one that isn't seen on our straight-edged tools, so this was very cool to see (though they weren't grinding on the day).

Nisaku graciously allowed Christian to grab some phone footage of what was going on across the production floor on the day he was there. Join him for a sticky beak by clicking the photo below.

A big thank-you to the Nisaku team for hosting Christian on a cold February morning - we hope you enjoy this peek inside a factory that produces some truly revolutionary gardening tools.