The JTA Blog

-

-

Shokunin Kishitsu | The Spirit of the Artisan

What is it about a Japanese tool that captivates us? Is it the blade’s fearsome sharpness, the handle’s perfect balance, or the elegant simplicity of its form? Whether you are...

-

-

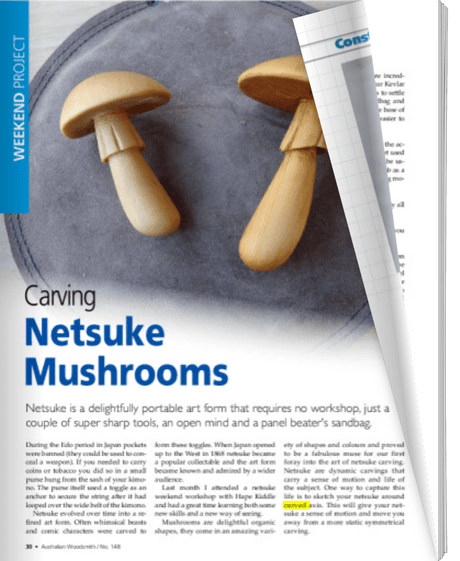

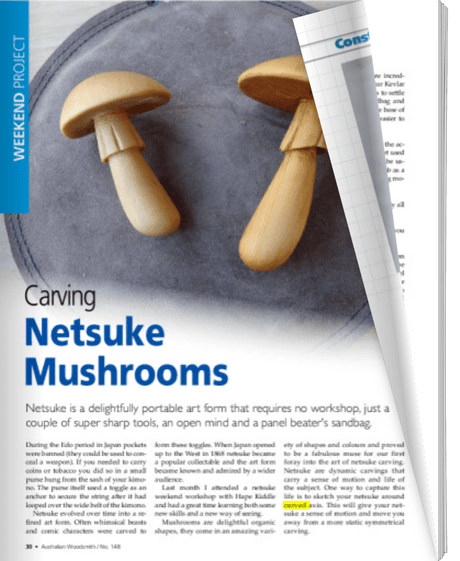

Carving Netsuke Mushrooms

Download PDF

-

Using the Shinwa NEXT Saw guides

Shinwa's Next Saw Guides are the table saw you can fold up and take with you. Unlike a track saw, they need no extra attachments to register square on sheet...

-

About Star-M Precision Tools

Established over 100 years ago in Miki city, Japan, STAR-M specialise in the production of drill bits and are the preferred brand amongst Japanese woodworkers. Chronology 1923 Motoji Kobayashi started...

-

Why use a Ryoba saw?

The ObviousAs with all Japanese saws, Ryoba saws cut on the pull stroke. This means that the blade is under tension as it cuts, and is pulled straight as it...

-

The World's Best

What could you achieve if you spent your career focused on one task? If you worked ten hours a day, six days a week, on one craft and one job,...

-

Japanese Coaster DIY Project

Making this set of 4 Japanese drinks coasters is a great simple introductory project. Perfect for kids and first-time woodworkers. Made from cypress and handcrafted with the traditional Japanese technique...

-

Build a Traditional Japanese Wooden Toolbox

Watch the instruction video in Fullscreen mode here. At JTA we are keenly aware that there are many barriers to woodworking - fundamentally, the limitations of time, money and space will...

-

Sanjo Blacksmith Dojo

Dear Christian-san,We are sorry to inform you that we can no longer supply <one of your most beautifully crafted tools> due to the retirement of the smith. So goes the...

-

JTA Crew is heading to the Sydney Knife Show this weekend! 🙌🏻

JTA Crew is heading to the Sydney Knife Show this weekend! 🙌🏻 Will be joined by Nari from @hazuki.knives showing sharpening tips 🔪 Also if you spend over $200 with us at...

-

The JTA EOFY Warehouse Sale

Sat 24th & Sun 25th June 9-4pm. We have cleaned up the warehouse and need to find good homes for 100+ pre-loved, demo's, displays, overstock, factory seconds, lightly rusted or...

-

What Can You Find in an Old Japanese House?

On my recent trip to Japan, Douglas was very excited to hear about an old house that had recently been purchased and is under the process of renovation. Well, perhaps...

-

Kumagawa Wasen with Douglas Brooks - The Video Series

Kumagawa Wasen with Douglas Brooks - The Video Series This video series was shot in April/May 2023 when I travelled to the small town of Oda, Kagawa to lend a...

-

Visit us at Maleny Wood Festival

Established in 1996 by Barung Landcare, the Maleny Wood Expo promotes the sustainable use of our beautiful timbers through the work of local and regional wood artisans. The Wood Expo...

-

How are Japanese Carving Tools made - Visiting the Michihomono factory

It was destiny to stumble across Michihomono, one of Japan's most comprehensive, evolving, and unique carving tool makers. While living in Tokyo and walking home from my inlaw's workplace I...

-

Melbourne International Flower and Garden Show

We are headed to Carlton Gardens for the Melbourne International Flower and Garden Show from Wednesday March 29 to Sunday April 2. We've brought in an amazing selection of new...

-

Sourcing Timber for a Japanese Wooden Boat

By far the most difficult part of preparing to build two boats with Douglas Brooks has been sourcing timber that meets our needs in Australia. The short version is, we...

-

Echigofuruzai Iguchi Lumber Co

This would have to be one of the most amazing and biggest collections of reclaimed building materials from houses, shrines and Kura that we have ever seen. Definitely worth the...

-

Carving Spoon Blanks

We have been lucky enough to come into possession of offcuts of Huon Pine. Those familiar with this precious golden timber will know that it is amongst the most slow-growing...

-

Marking and Measuring - Bonus Facet

The kiridashi is a beautiful tool. This year Hiroshi Yamaguchi, while running his box making class, showed us a little trick for making these amazingly accurate tools even more versatile....

-

It's NOT Black Friday - so why are these deals so damn good?

For the last three years we have put up a bit of a sale for Black Friday, and for the last three years we have received emails from customers lamenting...

-

An Apprentice Boat Builder in Japan

Japan's hand-crafted wooden boats, admired for their timeless beauty and precise construction, have a rich history in the island nation. Fearing that the techniques, designs and secrets of this trade...

-

Goto Island Bucket Making

Traditional crafts in Japan are a beautiful but delicate thing. Our business relies on skills that, once plentiful, are increasingly the domain of a group of people that grows smaller...

-

Touring the Shinwa Sashigane and ruler factory in Sanjo

The Shinwa brand was formed in 1971, after three competing Sanjo-based makers of traditional sashigane squares merged to form a single company. Before continuing, it is important to mention the...

-

The 'Shedding house' Echigo Tsumari Art Field

Once every 3 years, Niigata prefecture holds a massive art trail. Amongst art galleries and public spaces, many old buildings have been repurposed. What else would you do with 9...

-

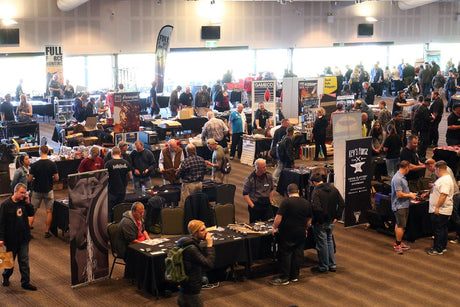

Sydney Knife Show & Getting Stroppy at JTA

Come see us at the Sydney knife show this weekend at Rose Hill Race Course Saturday and Sunday from 9 am to 4 pm SAT 6th - SUN 7th AUG...

-

Sawing techniques to perfect the art of using the Japanese saw

Mitch Got to Pick Greg's Brain about saws - listen along for some great tips on getting the most out of your saw.

-

Flattening Waterstones

Waterstones are our preferred way of sharpening all of our tool and knife edges, however, there is a need to maintain waterstones during and after use in order to get...

-

Know the difference between Silky Tooth Style's

NON SET TOOTHWhat does this mean?The teeth are “non-set”, so that the cutting surface cuts straight into the wood and destroys about 50% less wood cells in the process. The...

-

Using our Chopstick Jig to make your own Chopsticks

Our chopstick-making jig is ingenious in its simplicity, but does require a little bit of practice to get it turning out perfect utensils every time. Here are the steps to...

-

Understanding the Japanese Saw

Japanese saws are distinctive from western hand saws in a few crucial ways, most of which rely on the fact that they cut on the pull-stroke. Since the blade...

-

Making the Most of Our Complete Sharpening Kit

If you have recently purchased our Complete Sharpening Kit as an introduction to the world of hand-, jig- or waterstone-sharpening, congratulations! With a high quality ceramic Japanese waterstone and the...

-

Using Waterstones - The Essentials

It is essential to follow a few basic principles to get the best out of any waterstone. Keep your stone flat by dressing its surface with a flat, coarse abrasive. Adhesive-backed sandpaper...

-

Sydney Knife Show 2018

Once a year JTA ventures beyond the boundaries of the traditional woodworking community and finds itself wide-eyed and somewhat warily setting up shop at the Sydney knife show, which this...

-

WA Woodshow 2018

The Western Australian Woodshow on the 3rd, 4th & 5th of August at Claremont Showgrounds will be our final event on the west coast for the year, but promises to be...

-

Whetstones, Wetstones, Waterstones & Water Stones

We are often asked about using whetstones, wetstones and water stones for sharpening tools and knives, so we thought we’d take a moment to clear up the confusion. Water stones...

-

Using Japanese hand tools course with Hiroshi Yamaguc

Early this year I was privileged to attend a wood working class run by a Japanese craftsman at the ANU in Canberra. Hiroshi Yamaguchi was wonderful at describing how to use...

-

THE JAPANESE TOOLS AND LEGACY NAUTICAL SET DESIGNED SPECIFICALLY FOR BOAT BUILDING

Japanese Tools Australia and Legacy Nautical Boat Builders proudly present the first Japanese Tools Set designed specifically for boat building. View it in the shop here. This set contains 19...

-

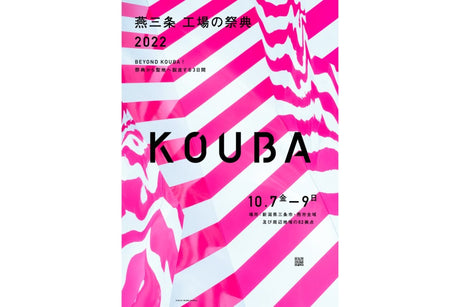

THE TSUBAME-SANJO FACTORY FESTIVAL

You will find exciting new tools at the Timber shows next year Below you will find some pictures from this year’s festival. Waterstones at Sanjo City Blacksmith Centre. Annealing copper...