- Notify Me

- Notify Me

- Notify Me

- Notify Me

- Notify Me

- Notify Me

- Bundle DiscountSave 10%

- Notify Me

- Notify Me

- Notify Me

- Notify Me

Featured Products

View all

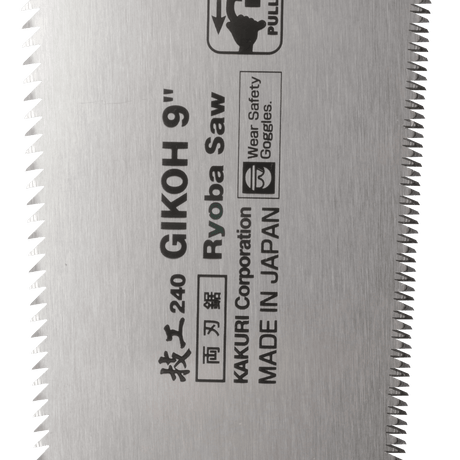

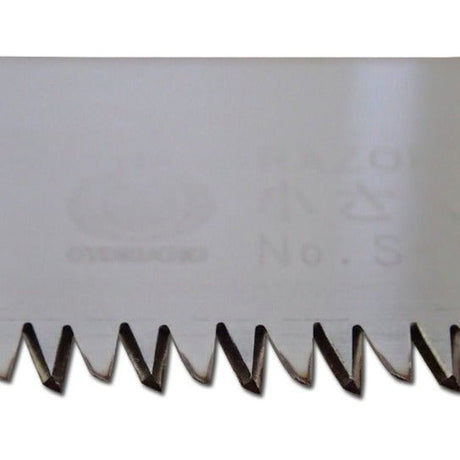

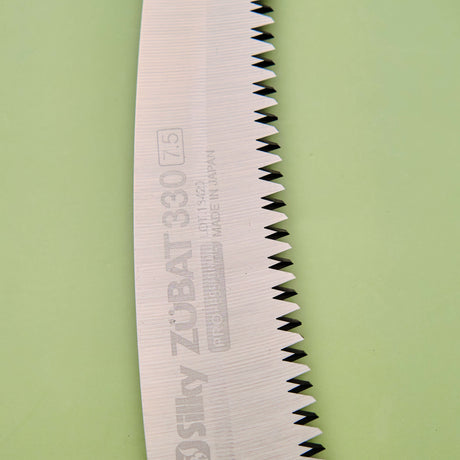

Japanese saws are distinctive from western hand saws in a few crucial ways, most of which rely on the fact that they cut on the pull-stroke. Since the blade of the saw cuts as it is drawn towards the user, rather than as it is pushed away, the blade is constantly in tension while cutting. This means that the saw plate can be made of very thin metal, even for saws designed to rip boards. In turn, because these saws leave a fine kerf, they remove less material as they cut and therefore are extremely efficient, requiring less effort and time compared to a similarly sized Western counterpart with a greater blade thickness.

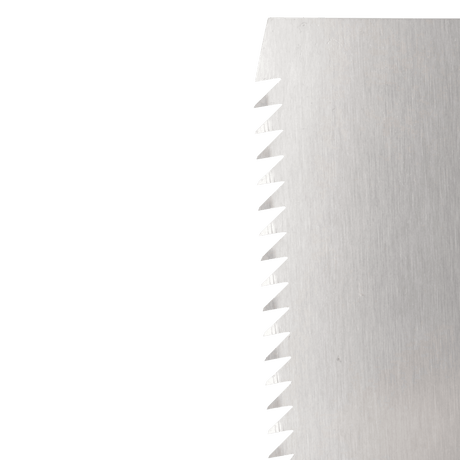

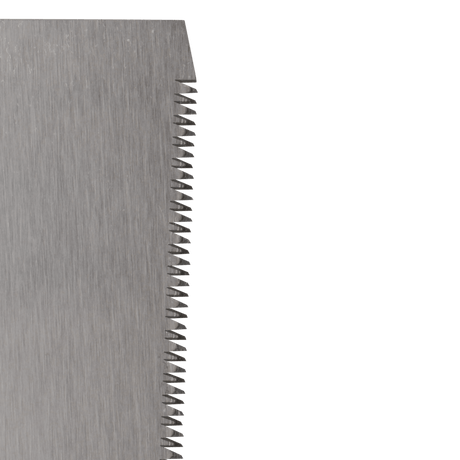

The sizing of teeth in Japanese saws is generally directionally proportional to the size of the saw itself. A larger saw usually means a larger tooth pattern, meaning a saw can cut faster and more aggressively, but the finish it leaves will be rougher. The smaller a Japanese saw is, the finer the teeth, which are capable of leaving extremely fine surfaces, but require more strokes to achieve the same cut. Japanese saw teeth are also graduated along the saw blade — often, the teeth closest to the handle are smaller and finer than the teeth farthest away, which are intentionally larger. This allows the user to start the cut with the fine teeth and progress to the more aggressive teeth once a kerf has been established.